Skype: +86 193 3849 2153

EMAIL: Nancy@jnhgbf.com

| TECHNICAL DATA | |

| Material: | F46/HT200 |

| DN: | 20mm-100mm |

| PN: | 16bar |

| Q: | 1.5m³/h-100m³/h |

| H: | 10m-55m |

| T: | -20°C-120°C |

| P: | 1.5kw-18.5kw |

Send E-mail:Nancy@jnhgbf.com

| N | Model | Rev=2900r/min Medium density=1000kg/m ³ | |||||||

| Flow | Pump head | η | Inlet | Outlet | Npsh | Power | Weight | ||

| (m³/h) | (m) | (%) | (mm) | (mm) | (m) | (kw) | (kg) | ||

| 1 | 25FSB-10 | 1.5 | 10 | 25 | φ25 | φ20 | 3 | 1.5 | 48 |

| 2 | 25FSB-18 | 3.6 | 18 | 27 | φ25 | φ20 | 3 | 2.2 | 48 |

| 3 | 25FSB-25 | 3.6 | 25 | 27 | φ25 | φ20 | 3 | 2.2 | 48 |

| 4 | 40FSB-15 | 5 | 15 | 40 | φ40 | φ32 | 3 | 3 | 75 |

| 5 | 40FSB-20 | 5 | 20 | 42 | φ40 | φ32 | 3 | 3 | 75 |

| 6 | 40FSB-30 | 10 | 30 | 42 | φ40 | φ32 | 3 | 3 | 75 |

| 7 | 50FSB-25 | 12.5 | 25 | 43 | φ50 | φ32 | 3.5 | 3 | 75 |

| 8 | 50FSB-30 | 12.5 | 30 | 42 | φ50 | φ32 | 3.5 | 3 | 75 |

| 9 | 65FSB-32 | 25 | 32 | 45 | φ65 | φ50 | 3.5 | 5.5 | 120 |

| 10 | 80FSB-20 | 50 | 20 | 45 | φ80 | φ65 | 3.5 | 5.5 | 130 |

| 11 | 80FSB-25 | 50 | 25 | 50 | φ80 | φ65 | 3.5 | 7.5 | 145 |

| 12 | 80FSB-30 | 50 | 30 | 59 | φ80 | φ65 | 4 | 7.5 | 145 |

| 13 | 80FSB-40 | 50 | 40 | 48 | φ80 | φ50 | 4 | 11 | 195 |

| 14 | 80FSB-50 | 50 | 50 | 57 | φ80 | φ50 | 4 | 15 | 210 |

| 15 | 80FSB-55 | 50 | 55 | 50 | φ80 | φ50 | 4 | 18.5 | 230 |

| 16 | 100FSB-32 | 100 | 32 | 68 | φ100 | φ80 | 3.5 | 15 | 250 |

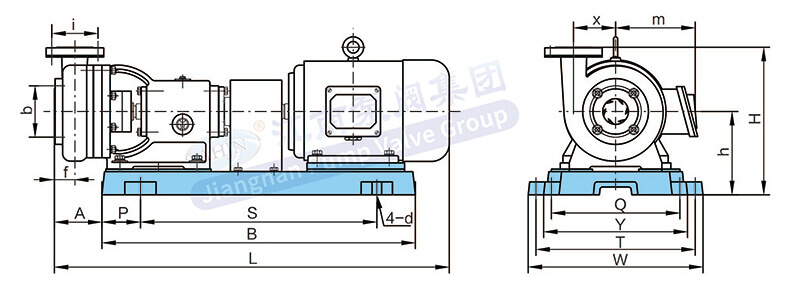

| N | Model | Outside and installing size | ||||||||||||||

| L | B | S | P | A | W | T | Y | Q | H | h | f | x | m | 4-φC | ||

| 1 | 25FSB-10 | 786 | 610 | 455 | 85 | 107 | 325 | 285 | 280 | 250 | 287 | 162 | 58 | 82 | 180 | 4-Ф16 |

| 2 | 25FSB-18 | 786 | 610 | 455 | 85 | 107 | 325 | 285 | 280 | 250 | 287 | 162 | 58 | 82 | 180 | 4-Ф16 |

| 3 | 25FSB-25 | 786 | 610 | 455 | 85 | 107 | 325 | 285 | 280 | 250 | 287 | 162 | 58 | 82 | 180 | 4-Ф16 |

| 4 | 40FSB-15 | 786 | 610 | 455 | 85 | 107 | 325 | 285 | 280 | 250 | 287 | 162 | 58 | 82 | 180 | 4-Ф16 |

| 5 | 40FSB-20 | 786 | 610 | 455 | 85 | 107 | 325 | 285 | 280 | 250 | 287 | 162 | 58 | 82 | 180 | 4-Ф16 |

| 6 | 40FSB-30 | 786 | 610 | 455 | 85 | 107 | 325 | 285 | 280 | 250 | 287 | 162 | 58 | 82 | 180 | 4-Ф16 |

| 7 | 50FSB-25 | 786 | 610 | 455 | 85 | 107 | 325 | 285 | 280 | 250 | 287 | 162 | 58 | 82 | 180 | 4-Ф16 |

| 8 | 50FSB-30 | 786 | 610 | 455 | 85 | 112 | 325 | 280 | 275 | 230 | 287 | 162 | 58 | 82 | 180 | 4-Ф16 |

| 9 | 65FSB-32 | 940 | 715 | 480 | 130 | 142 | 370 | 330 | 290 | 250 | 347 | 197 | 74 | 95 | 210 | 4-Ф16 |

| 10 | 80FSB-20 | 980 | 715 | 480 | 130 | 142 | 370 | 330 | 290 | 250 | 347 | 197 | 74 | 95 | 210 | 4-Ф16 |

| 11 | 80FSB-25 | 980 | 715 | 480 | 130 | 142 | 370 | 330 | 285 | 250 | 347 | 197 | 74 | 95 | 210 | 4-Ф16 |

| 12 | 80FSB-30 | 980 | 715 | 480 | 130 | 142 | 365 | 330 | 340 | 240 | 347 | 197 | 74 | 95 | 210 | 4-Ф16 |

| 13 | 80FSB-40 | 1096 | 840 | 660 | 90 | 142 | 430 | 390 | 340 | 300 | 410 | 230 | 85 | 118 | 265 | 4-Ф16 |

| 14 | 80FSB-50 | 1096 | 855 | 655 | 100 | 142 | 430 | 400 | 340 | 310 | 410 | 230 | 85 | 118 | 265 | 4-Ф16 |

| 15 | 80FSB-55 | 1141 | 840 | 830 | 90 | 142 | 430 | 390 | 340 | 300 | 410 | 230 | 85 | 118 | 265 | 4-Ф16 |

| 16 | 100FSB-32 | 1320 | 1270 | 830 | 215 | 142 | 500 | 440 | 350 | 440 | 500 | 280 | 100 | 118 | 265 | 4-Ф24 |

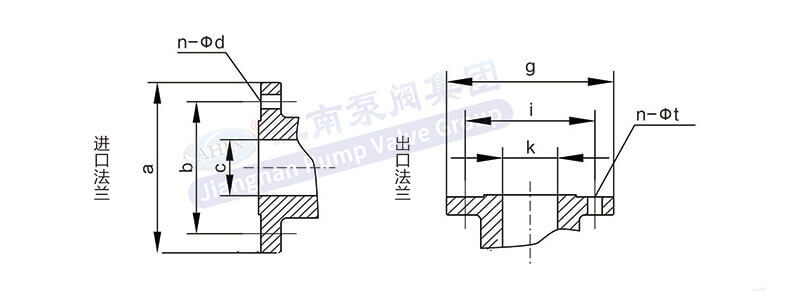

| N | Model | Inlet flange size | Exit flange size | ||||||||

| c | a | b | e | n-d | k | g | i | j | n-t | ||

| 1 | 25FSB-10 | 25 | 100 | 85 | 18 | 4-M10 | 20 | 100 | 75 | 15 | 4-Ф11.5 |

| 2 | 25FSB-18 | 25 | 100 | 85 | 18 | 4-M10 | 20 | 100 | 75 | 15 | 4-Ф11.5 |

| 3 | 25FSB-25 | 25 | 130 | 100 | 18 | 4-M12 | 20 | 112 | 90 | 18 | 4-Ф11.5 |

| 4 | 40FSB-15 | 40 | 130 | 100 | 18 | 4-M12 | 32 | 112 | 90 | 18 | 4-Ф11.5 |

| 5 | 40FSB-20 | 40 | 130 | 100 | 18 | 4-M12 | 32 | 112 | 90 | 18 | 4-Ф11.5 |

| 6 | 40FSB-30 | 40 | 130 | 100 | 18 | 4-M12 | 32 | 112 | 90 | 18 | 4-Ф11.5 |

| 7 | 50FSB-25 | 50 | 130 | 100 | 18 | 4-M12 | 32 | 112 | 90 | 18 | 4-Ф11.5 |

| 8 | 50FSB-30 | 50 | 130 | 100 | 18 | 4-M12 | 32 | 112 | 90 | 18 | 4-Ф11.5 |

| 9 | 65FSB-32 | 65 | 185 | 150 | 18 | 4-M12 | 50 | 160 | 130 | 22 | 4-Ф12 |

| 10 | 80FSB-20 | 80 | 185 | 150 | 18 | 4-M12 | 65 | 160 | 130 | 22 | 4-Ф12 |

| 11 | 80FSB-25 | 80 | 185 | 150 | 18 | 4-M12 | 65 | 160 | 130 | 22 | 4-Ф12 |

| 12 | 80FSB-30 | 80 | 185 | 150 | 18 | 4-M12 | 65 | 160 | 130 | 20 | 4-Ф13 |

| 13 | 80FSB-40 | 80 | 190 | 150 | 18 | 4-Ф16 | 50 | 170 | 125 | 20 | 4-Ф17.5 |

| 14 | 80FSB-50 | 80 | 190 | 150 | 18 | 4-Ф17.5 | 50 | 170 | 125 | 20 | 4-Ф17.5 |

| 15 | 80FSB-55 | 80 | 190 | 150 | 20 | 4-Ф17.5 | 50 | 170 | 125 | 20 | 4-Ф17.5 |

| 16 | 100FSB-32 | 100 | 220 | 180 | 25 | 4-M16 | 80 | 200 | 165 | 25 | 4-M16 |

Name: jiangnan pump

For: share openings, doing business, make information transmission

Click it to Join in